Flat and Round Drop Cable Pigtail

With Hardened SC/APC (OptiTap) Connector

OptiTap Cable Assembly is factory -terminated, environmentally

sealed and hardened connector to reduce the cost and the time of

drop cable deployment in optical access networks. OptiTap connector

assemblies provide a robust and sealed connection solution for FTTX

connectivity. The hardened connector end incorporates an SC/APC

type connection within a slim, sealed, threaded polymer housing

allowing easy connection to either a multiport terminal or in-line

extension receptacle. The SC/APC connector mates to a standard

adapter, providing a common interface. Available with flat drop or

traditional round style outdoor cables, the hardened connector

provides an ideal solution for direct burial, conduit, or aerial

installations. The OptiTap. Single -Fiber Drop Cable Assembly is

specifically designed to significantly reduce required drop cable

installation

G657.B3 Optical Fiber Characteristics

| Parameter | conditions | Units | value |

| Optical |

| Attenuation | 1310 nm | dB/km | ≤0.350 |

| 1383 nm | dB/km | ≤0.330 |

| 1550 nm | dB/km | ≤0.210 |

| 1625 nm | dB/km | ≤0.230 |

Attenuation vs. Wavelength | 1310 nm VS. 1285‐1330 nm | dB/km | ≤0.05 |

| 1550 nm VS. 1525‐1575 nm | dB/km | ≤0.04 |

| Zero Dispersion Wavelength | | nm | 1300-1324 |

| Zero Dispersion Slope | ps/(nm2∙km) | ≤0.092 |

| Polarization Mode Dispersion (PMD) | — | — |

| Maximum Individual Fiber | ps/√km | 0.2 |

| Link design value (M=20, Q=0.01%) | ps/√km | 0.1 |

| Cut‐off Wavelength λcc | | nm | ≤1260 |

Mode Field Diameter (MFD) | 1310 nm | μm | 8.6±0.4 |

| 1550 nm | μm | 9.6±0.5 |

Attenuation Discontinuity | 1310 nm | dB | ≤0.03 |

| 1550 nm | dB | ≤0.03 |

Bidirectional Attenuation | 1310 nm | dB/km | ≤0.05 |

| 1550 nm | dB/km | ≤0.05 |

Attenuation Nonuniformity | 1310 nm | dB/km | ≤0.05 |

| 1550 nm | dB/km | ≤0.05 |

| Geometrical |

| Cladding Diameter | μm | 125±0.7 |

| Cladding Non‐Circularity | % | ≤0.8 |

| Core/Cladding Concentricity Error | μm | ≤0.5 |

| Coating Diameter (Uncolored) | μm | 242±7 |

| Coating/Cladding Concentricity Error | μm | ≤12 |

| Curl | m | ≥4 |

| Environmental (1310nm, 1550nm) |

Temperature Cycling | ‐60℃ to +85℃ |

dB/km |

≤0.05 |

High Temperature & High Humidity | 85℃ at 85% RH |

dB/km |

≤0.05 |

Water Immersion | 23℃ |

dB/km |

≤0.05 |

High Temperature Aging | 85℃ |

dB/km |

≤0.05 |

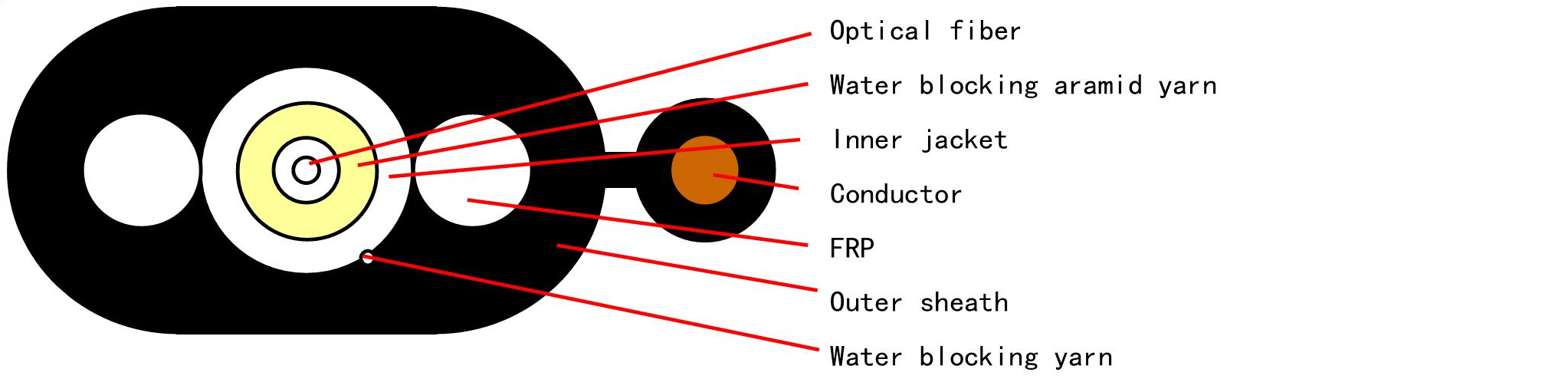

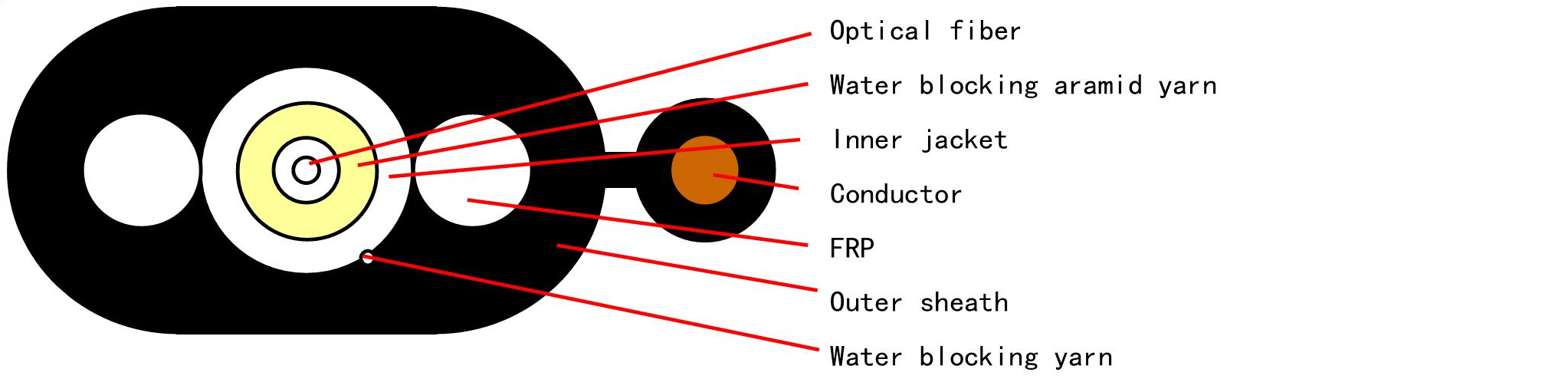

Type1: GYFJXBY-1B6 8.1mm×4.5mm Flat Drop Cable Specifications

Cable Profile view

Technology specification

| Item | Technology parameter |

| Cable type | GYFJXBY-1B6 |

| Strength member | Plastic coated FRP (*2) |

| Strength member diameter mm | 1.6*1.7 |

| Outer sheath color | Black |

| Outer sheath material | PE |

| Outer sheath dimension mm | 8.1(±0.4)×4.5(±0.4) |

Min. bending radius mm | 100 (Static) 150(Dynamic) |

| Attenuation dB/km | ≦ 0.4 at 1310nm, ≦ 0.3 at 1550nm |

| Short term tensile N | 1350 |

| Long term tensile N | 400 |

| Crush resistance N/100mm | 2000 |

| Operation temperature ℃ | -40~+70 |

| Optical unit |

| Fiber type | 9/125 (G.657B3) |

| Fiber color | Natural |

| Tight buffer diameter mm | 0.9±0.05 |

| Tight buffer color | White |

| Strength member | Water blocking aramid yarn |

| Inner jacket material | LSZH |

| Inner jacket diameter mm | 2.9±0.1 |

| Inner jacket color | White |

Note: the product is in accord with the instruction of EU RoHS2.0

Type2: GDFJXBY-1B6+1× 24AWG 10.1mm×4.5mm Flat Drop Cable with

conduct Specifications

Profile view

Technology specification

| Item | Technology parameter |

| Cable type | GDFJXBY-1B6+1×24AWG |

| Strength member | Plastic coated FRP (*2) |

| Strength member diameter mm | 1.6*1.7 |

| Outer sheath color | Black |

| Outer sheath material | PE |

| Outer sheath dimension mm | 10.1(±0.5)×4.5(±0.5) |

| Min. bending radius mm | 100 (Static) 150(Dynamic) |

| Attenuation dB/km | ≦ 0.4 at 1310nm, ≦ 0.3 at 1550nm |

| Short term tensile N | 1350 |

| Long term tensile N | 400 |

| Crush resistance N/100mm | 2000 |

| Operation temperature ℃ | -40~+70 |

| Optical unit |

| Fiber type | 9/125 (G.657B3) |

| Fiber color | Natural |

| Tight buffer | 0.9±0.05 |

| Tight buffer color | White |

| Strength member | Water blocking aramid yarn |

| Inner jacket material | LSZH |

| Inner jacket diameter mm | 2.9±0.1 |

| Inner jacket color | White |

| Electrical unit |

| Conductor AWG | 24 AWG |

| Conductor material | Copper wire |

| Normal conductor diameter mm | 0.511 |

| Normal insulation diameter mm | 2.0 |

Note: the product is in accord with the instruction of EU RoHS2.0

Type3: GYFJXY-1B6 5.4mm Round Drop Cable

Profile view

Technology specification

| Item | Technology parameter |

| Cable type | GYFJXY-1B6 |

| Fiber type | 9/125 (G657B3) |

| Fiber color | Natural |

| Tight buffer | 0.9±0.05 |

| Tight buffer color | White |

| Strength member | Aramid yarn |

| Inner jacket diameter mm | 1.65±0.1 |

| Inner jacket color | White |

| Inner jacket material | LSZH |

| Strength member | Plastic coated FRP (*2) |

| Strength member diameter mm | 1.4*1.5 |

| Outer sheath color | Black |

| Outer sheath material | PE |

| Outer sheath dimension mm | 5.4±0.2 |

| Cable weight Kg/km | Approx. 28.5 |

Min. bending radius mm | 10D (Static) 20D (Dynamic) (D: Cable diameter) |

| Attenuation dB/km | ≦ 0.4 at 1310nm, ≦ 0.3 at 1550nm |

| Short term tensile N | 1350 |

| Long term tensile N | 400 |

| Crush resistance N/100mm | 1500 |

| Operation temperature ℃ | -40~+70 |

| Installation temperature ℃ | -30~+70 |

| Storage temperature ℃ | -40~+70 |

Note: the product is in accord with the instruction of EU RoHS 2.0

OptiTap Hardened Optical Cable Assembly Specifications

| Parameters | Specifications |

| Applicable Cable | Type1: 8.1mm×4.5mm Flat Drop Cable Type2: 10.1mm×4.5mm Flat Drop Cable with conduct Type3: 5.4mm Round Drop Cable |

| Connector Type Side A | 1pc Optitap SC/APC type water-proof connector |

| Connector Type Side B | No connector |

| Fiber Type | G657B3 |

| Fiber Core | 1 fiber |

| Cable Length | 20~300m |

| Insertion Loss (dB) | ≤ 0.3 (Maximum value) |

| Returned Loss (dB) | ≥60 (for APC) |

| Operating Temperature (℃) | -40 ~ +85 |

| IP Lever | IP68 |

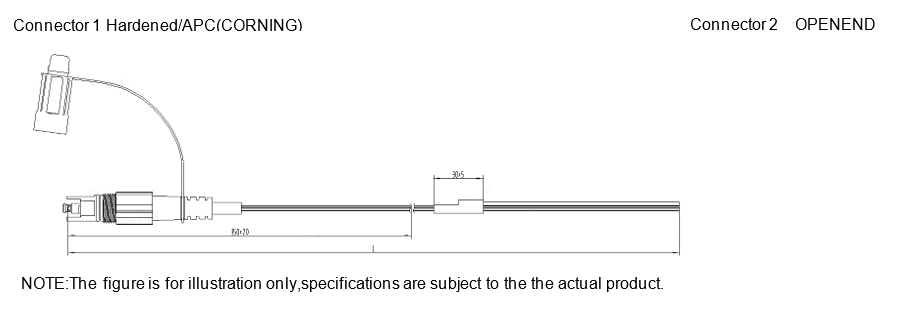

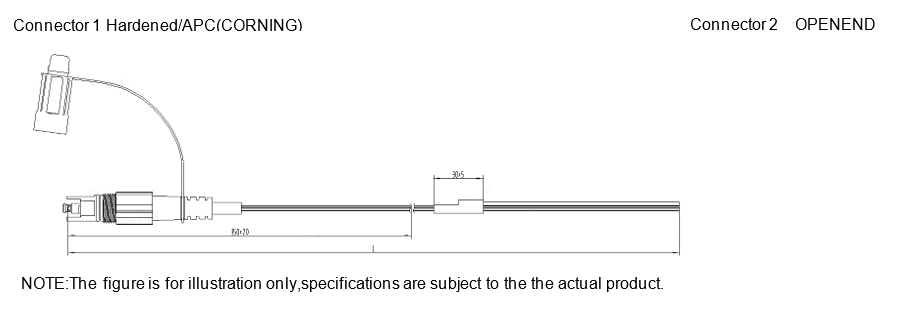

Drawing

| NO. | SIDE A: Connector 1 | SIDE B: Connector 2 |

| 1 | Hardened/APC (OptiTap) | OPENEND |

Optical Performance

| Item | Connector 1(Hardened/APC) | Connector 2(OPENEND) |

| IL (max) | 0.3dB | / |

| RL (min) | 60dB | / |

- IL Test:

Test Standard:IEC61300-3-4 (insertion method B)

Test Wavelength:1310nm&1550nm

IL:See table 4

Note: 50m and above according to insertion loss 0.3dB+ cable loss

(according to 0.4dB/km)

- Return Loss Test

Test Standard:IEC61300-3-6 (OTDR method)

Test Wavelength:1310nm&1550nm

RL:See table 4

- Connector End Face Inspection

Test Standard:IEC 61300-3-35

Note:400X Zoom

| Area | End Face Acceptance |

| Protruding point | scratch |

| A | ≤25um | Not Allowed | Not Allowed |

| B | 25~120um | <1um:NOT Limited

≤3um:3pcs | White scratch ≤1um; No limit ≤2um: 3 pieces; > 2um not allowed; Black scratches: Not allowed |

| C | 120~130um | Non-wipeable particle | Allowed ≤3um:2pcs |

| D | 130~250um | Non-wipeable particle | Allowed ≤10um:2pcs |

- Geometry

Test Standard:IEC 61755-3-2

| Item | Connector 1(Hardened/APC) | Connector 2(OPEN) |

| Fiber height | -100nm~50nm | / |

| Radius | 5mm~12mm | / |

| Apex offset | 0~70μm | / |

| Angle | 8±0.3° | / |

| Ferrule diameter | 2.4985mm~2.4995mm | / |

Mechanical Performance

| Item | Initial test | During test | After test |

| Insertion loss (Max). | 0.3dB | / | / |

| Maximum amount of insertion loss change (pigtail). | / | 0.2dB | 0.2dB |

| Maximum amount of insertion loss change (patchcord). | / | 0.5dB | 0.4dB |

| Return loss (Min). | 60dB | 60dB | 60dB |

Table 5 Test Process Performance Requirements

| serial number | Pilot project | Reference standards and test methods | request |

| 1 | Coupling force of the locking mechanism | Test standard: IEC 61300-2-6 Test wavelength: 1310nm&1550nm For Connector 1, load: 215N at 5 N/s Duration: 120s Load position: 0.2m away from the tail end of the connector | Meet Table 5 online |

| 2 | Vibration Test (Sinusoidal) | Test standard: IEC61300-2-1 Test wavelength: 1310nm&1550nm Frequency range: 5Hz to 55 Hz Frequency variation: 1 oct/min Vibration direction: 30min in each of X, Y and Z directions Amplitude: 0.75mm | Meet Table 5 online

|

| 3 | Lateral loads | Test standard: IEC61300-2-42 Test wavelength: 1310nm&1550nm For Connector 1, load: 50N Duration: 1h Load position: 0.5m away from the tail end of the connector | Meet Table 5 online

|

| 4 | Drop test | Test Standard: IEC61300-2-12 Method B Test wavelength: 1310nm&1550nm Drop height: 1m Number of drops: 10 | Front and back meet Table 5

|

| 5 | Torsion test | Test standard: IEC61300-2-5 Test wavelength: 1310nm&1550nm Tensile load: 15N at 1N/s Tensile load application point: 0.2m from the tail end of the

connector Duration of experiment: 10 cycles, ± 180° | Meet Table 5 online |

| 6 | Repeated bending | Test standard: IEC61300-2-44 Test wavelength: 1310nm&1550nm For Connector 1, load: 15N, ± 90°, 50 cycles Distance from the load point: 0.2 m from the tail end of the

connector | Meet Table 5 online

|

| 7 | Durability tested | Test standard: IEC61300-2-2 Test wavelength: 1310nm&1550nm Repeat plugging and unplugging with adapter: 500 times Cycle rate: The time of each plugging and unplugging is not less

than 3s, and the data is recorded once every 25 times of plugging

and unplugging Number of cleanings: no more than 25 times | Front and back meet Table 5

|

Environmental performance

| serial number | Pilot project | Reference standards and test methods | request |

| 1 | Temperature cycling | Test standard: IEC61300-2-22 Test wavelength: 1310nm&1550nm Temperature: -25°C~+65°C Extreme temperature holding time: 1h Rate of temperature change: 1°C/min Number of cycles: 12 cycles | Meet Table 5 online |

| 2 | Low temperature aging | Test standard: IEC61300-2-17 Test wavelength: 1310nm&1550nm Temperature: -25°C Duration of exposure: 96h Sampling rate: record the initial values of insertion loss and

return loss after 2 hours of storage at room temperature, record

the values of insertion loss and return loss every 1 hour after

reaching the stable test temperature as the process value, and

record the final values of insertion loss and return loss after the

sample returns to room temperature for 2 hours after the low

temperature process is over | Meet Table 5 online |

| 3 | Aging at high temperatures | Test standard: IEC61300-2-18 Test wavelength: 1310nm&1550nm Temperature: 75°C Duration of exposure: 96h Sampling rate: record the initial value of insertion loss and

return loss after storing at room temperature for 2h, record the

value of insertion loss and return loss every 6h after reaching the

stable test temperature, and record the final value of insertion

loss and return loss after the sample returns to room temperature

for 2h after the high temperature process is over | Meet Table 5 online |

| 4 | High humidity aging test | Test standard: IEC61300-2-19 Test wavelength: 1310nm&1550nm Temperature: 40°C Humidity: 93 % ± 5 % Duration of exposure: 96h Sampling rate: record the initial values of insertion loss and

return loss after 2 hours of storage at room temperature, record

the values of insertion loss and return loss every 1 hour after

starting the test, and record the final values of insertion loss

and return loss after the cycling process | Meet Table 5 online There is no damage or abnormality such as cracking, discoloration,

precipitation, etc |

| 5 | Water resistance test | Test standard: IEC60529 IEC 61300-2-23 Method 2 Test 1: Water depth: 5m, Connector 1 immersed in water, duration:

stand for 7days; Test requirements: observe that there is no water

immersion in the connector; Test 2: Connect Connector 1 to the box of the adapter, inject 20KPa

air pressure into the box, duration: 15min; | No water leakage or air leakage |

Package (Thin film winding and carton packing)

Picture just for reference